Ukuqonda I-Thin-Film Technology

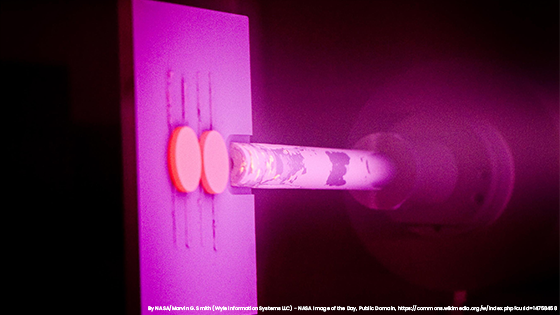

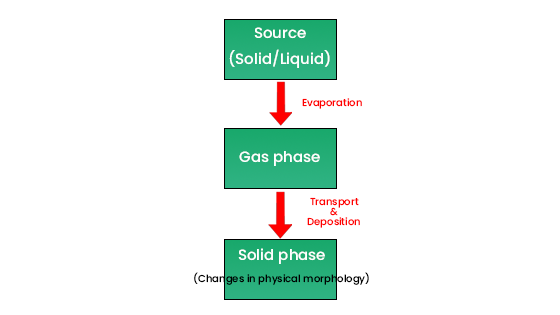

Ubuchwepheshe befilimu izacile buhilela ukufaka izingqimba zensimbi (imvamisa ukusuka kuma-nanometer ambalwa kuye kokuwugqinsi kwama-micrometer ambalwa) ku-substrate. Lezi zingqimba zingenziwa ngezinsimbi, ama-semiconductors, ama-insulators, noma ezinye izinto, futhi zisetshenziselwa ukwakha izingxenye ze-elekthronikhi ezisebenzayo. Lobu buchwepheshe bubaluleke kakhulu ekukhiqizeni izinto zikagesi njengoba buvumela ukunemba okuphezulu nokusebenza kwezingxenye. I-Thin-film deposition yenziwa nge- physical vapor deposition (PVD) noma i-chemical vapor deposition (CVD), iqinisekisa ikhwalithi nokusebenza komkhiqizo wokugcina.

Ukuthuthukiswa kobuchwepheshe befilimu emincane kuhlehlela emuva maphakathi nekhulu lama-20 lapho kwenziwa intuthuko enkulu kwezesayensi yezinto ezibonakalayo kanye namasu okufakwa kwe-vacuum. Ekuqaleni, ubuchwepheshe befilimu emincane babusetshenziswa ikakhulukazi embonini ye-semiconductor ekwenzeni ama-transistors namasekethe ahlanganisiwe. Njengoba ubuchwepheshe buthuthuka kanye nesidingo sikhula, uhla lokusetshenziswa kobuchwepheshe befilimu elincanyana lwanda ngokushesha. Namuhla, isetshenziswa kabanzi ekukhiqizeni izinzwa, i-optical coatings, amaseli elanga, ama-hard disk drives, nama-anti-corrosion coatings, phakathi kokunye. Isibonelo, ekukhiqizeni izinzwa, ubuchwepheshe befilimu encane busetshenziselwa ukukhiqiza izinzwa zokucindezela, izinzwa zegesi, nezinzwa zokushisa, ezibonakala ngokuzwela okuphezulu nokunemba. Ukwengeza, ukusetshenziswa kobuchwepheshe befilimu encane ezinhlelweni ze-microelectromechanical (MEMS) kanye ne-nanotechnology nakho kuyakhula, kuhlinzeka ngosekelo olubalulekile lokusungula izinto ezintsha nentuthuko kule mikhakha.

Izici eziyinhloko zobuchwepheshe befilimu encane zifaka ukunemba kwayo okuphezulu, ukuguquguquka, kanye nekhono lokuhlanganisa imisebenzi eminingi. Ukunemba okuphezulu kuvumela ubuchwepheshe befilimu encane ukuthi bufinyelele izilinganiso ezinembe kakhulu phakathi kwebanga losayizi omncane, okubalulekile kumadivayisi afana nezinzwa zengcindezi ezidinga ukunakekela izilinganiso zengcindezi ezinembile ngaphansi kwezimo ezihlukahlukene zemvelo. Ukuvumelana nezimo kwamafilimu amancane kuwavumela ukuthi azivumelanise nama-substrates ahlukahlukene kanye nezidingo zohlelo lokusebenza, okwenza kube lula ukubeka ama-substrates ahlukene njenge-silicon, ingilazi, izinsimbi, namapulasitiki, ngaleyo ndlela afeze imisebenzi eminingi. Ngaphezu kwalokho, ubuchwepheshe befilimu encane bungahlanganiswa nobunye ubuchwepheshe kanye nezinto zokwakha ukudala amadivaysi ayinhlanganisela anemisebenzi eminingi. Ngokwesibonelo, ukuhlanganisa ubuchwepheshe befilimu encane ne-MEMS kungakhiqiza izinzwa zokucindezela ezincane ezingagcini nje ngokuba zincane futhi zingasindi kodwa futhi ezizwela kakhulu futhi ezinokwethenjelwa.

Ubuchwepheshe befilimu encane futhi bungahlanganisa imisebenzi eminingi kudivayisi eyodwa, okusho ukuthi inzwa, ukukala, nokucubungula idatha kungafinyelelwa ngesikhathi esisodwa ngaphakathi kongqimba lwefilimu elincanyana, okwenza kube lula ukuklama kanye nenqubo yokukhiqiza idivayisi. Leli khono lokuhlanganisa aligcini nje ngokuthuthukisa ukusebenza nokuthembeka kwedivayisi kodwa futhi linciphisa izindleko zokukhiqiza nokuba yinkimbinkimbi. Ekuthuthukisweni kwezinzwa zokucindezela, ubuchwepheshe befilimu encane bungathuthukisa kakhulu ukusebenza kwezinzwa, bubavumele ukuthi basebenze ngokuzinza ezindaweni ezihlukahlukene eziyinkimbinkimbi.

Ukuhlanganiswa Kobuchwepheshe Befilimu Encane Ezinzwa Zengcindezi

Ukuhlanganiswa kobuchwepheshe befilimu encane kuzinzwa zokucindezela kuhloswe ukuthuthukisa ukusebenza, ukunciphisa usayizi, nokwandisa ukuzwela. Ngokulawula ngokunembile izakhiwo zezinto ezibonakalayo kanye nogqinsi lwesendlalelo, ubuchwepheshe befilimu encane benza ukuthuthukiswa kwezinzwa ezinemba okuphezulu kwenzeke. Lokhu kuhlanganiswa akuthuthukisi kuphela ukusebenza okuphelele kwezinzwa kodwa futhi kuletha izinzuzo ezibalulekile ezicini ezimbalwa ezibalulekile.

Okokuqala, ubuchwepheshe befilimu elincanyana buvumela ukwenziwa kancane kwezinzwa. Izinzwa zengcindezi evamile zivame ukubhekana nemikhawulo ngosayizi nesisindo, kuyilapho ubuchwepheshe befilimu encane buvumela ukwakhiwa kwezinzwa ezincane, ezilula ngaphandle kokuphazamisa ukusebenza. Lokhu kubaluleke kakhulu ezinhlelweni zokusebenza ezinendawo elinganiselwe noma ezidinga izixazululo ezingasindi, njengemishini yezokwelapha ne-MEMS.

Okwesibili, izinzwa zefilimu encane zihamba phambili ekuthuthukiseni ukuzwela. Ubuchwepheshe befilimu izacile bungathola izinguquko zomfutho wamaminithi ngokunemba okuphezulu, okwenza lezi zinzwa zibe nenzuzo ezindaweni ezidinga izilinganiso ezinembile. Isibonelo, ekusetshenzisweni okuzenzakalelayo kwezimboni nokuqapha kwemvelo, izinzwa zengcindezi yefilimu encane zinganikeza idatha enembile, ngaleyo ndlela zithuthukise ukusebenza kahle kwesistimu nokuthembeka.

Ngaphezu kwalokho, ubuchwepheshe befilimu encane buthuthukisa ukuthembeka nokuqina kwezinzwa zokucindezela. Ukufana okuphezulu nokuzinza kwezingqimba zefilimu elincanyana kuqinisekisa ukusebenza okungaguquki ekusebenziseni isikhathi eside. Uma kuqhathaniswa nezinzwa zendabuko, izinzwa zefilimu emincane zingagcina ukusebenza kahle ngisho nangaphansi kwezimo zemvelo ezimbi kakhulu, zizenze zisebenze kabanzi emikhakheni efana ne-aerospace kanye nezimboni zezimoto.

Uma kuqhathaniswa nezindlela zendabuko, ubuchwepheshe befilimu encane bunikeza enye indlela engasindi, ehlangene, futhi ezwela kakhulu. Izinzwa zengcindezi evamile zivame ukubhekana nezinselele ngosayizi, isisindo, nokunemba, kuyilapho ubuchwepheshe befilimu encane, nezakhiwo zayo eziphakeme kanye nezinqubo zokukhiqiza, bunqoba le mikhawulo. Izinzwa zefilimu ezacile azinazo nje izinzuzo ngosayizi nesisindo kodwa futhi zisebenza kahle kakhulu kunezinzwa zendabuko ngokunemba nokuzwela. Lezi zinzuzo zenza ubuchwepheshe befilimu encane ibe yingxenye ebalulekile yokuthuthukiswa kobuchwepheshe besimanje bezinzwa.

Izinto zokwakha ze-Thin-Film Pressure Sensors

Ukukhethwa kwezisetshenziswa zezinzwa zengcindezi emincane yefilimu kubalulekile njengoba lezi zinto ezisetshenziswayo zithinta ngqo ukusebenza nokuthembeka kwezinzwa.

Izinto Ezivamile

Izinto ezijwayelekile ezisetshenziswa kuzinzwa zengcindezi yefilimu elincanyana zifaka izinsimbi ezifana negolide, iplatinamu, ne-aluminium, ezaziwa ngokusebenza kwazo okuhle kakhulu nokumelana nokugqwala. Igolide, njengento eqhuba kakhulu, ivame ukusetshenziswa ezingxenyeni ze-electrode zezinzwa ukuze kuqinisekiswe ukunemba nokuzinza kokudluliselwa kwesignali. I-Platinum, ngenxa yokuqina kwayo okuhle kakhulu kokushisa kanye nokumelana ne-oxidation, isetshenziswa kakhulu kuzinzwa zezindawo ezinokushisa okuphezulu. I-aluminium, ekubeni engasindi futhi nokuba ne-conductivity enhle, ivame ukusetshenziswa ezinhlelweni zezinzwa ezidinga ukulawula isisindo. Ukwengeza, izinto zokwakha ze-semiconductor ezifana ne-silicon ne-germanium zisetshenziswa kakhulu kuzinzwa zengcindezi yefilimu emincane ngenxa yezakhiwo zazo ezinhle zemishini nokuzwela, zidlala indima ebalulekile ku-MEMS.

Izinto Ezithuthukile

Ngokuthuthuka kobuchwepheshe, izinto ezithuthukisiwe ezifana nama-nanocomposites ne-graphene zithola ukunakwa okukhulayo kokusetshenziswa kwazo kuzinzwa zokucindezela kwefilimu emincane. Lezi zinto zicwaningwa kabanzi ngezakhiwo zazo ezinhle kakhulu namandla okuqhubeka nokuthuthukisa ukusebenza kwezinzwa. Ama-Nanocomposites ahlanganisa izinzuzo zezinto ezihlukahlukene, enikeza amandla aphakeme wemishini kanye ne-conductivity, engathuthukisa kakhulu ukuzwela kwezinzwa nokuqina. I-Graphene, enesakhiwo sesendlalelo se-athomu eyodwa kanye nezakhiwo zikagesi ezivelele, ithathwa njengenketho efanelekile yezinto ezisetshenziswayo zenzwa yesikhathi esizayo. Ayigcini nje ngokuba ne-ultra-high conductivity kodwa futhi ikhombisa amandla okusebenza kahle kakhulu nokunwebeka, okubonisa amandla amakhulu ekuthuthukisweni kwezinzwa zokucindezela ezizwela kakhulu.

Izinto ezibonakalayo

Ukukhethwa kwezinto zezinzwa zokucindezela kwefilimu emincane kusekelwe ezintweni zazo zikagesi, ezomshini, nezokushisa ukuze kuqinisekiswe ukusebenza kahle ngaphansi kwezimo ezihlukahlukene zokusebenza. Isibonelo, izinzwa ezisetshenziswa ezindaweni ezinokushisa okuphezulu zidinga izinto ezinokuzinza okuhle kakhulu kokushisa kanye nokumelana ne-oxidation, kuyilapho izinhlelo zokusebenza ezidinga ukuzwela okuphezulu zicabangela ukuqhutshwa kukagesi kanye ne-mechanical elasticity modulus yezinto. Ngokucabangela ngokucophelela lezi zakhiwo ezibonakalayo, abaklami bangakhetha izinto ezifanele kakhulu zezidingo ezithile zohlelo lokusebenza, baqinisekise ukwethembeka nokunemba kwezinzwa ezindaweni ezihlukahlukene eziyinkimbinkimbi.

Ukucatshangelwa Kwedizayini Yezinzwa Zokucindezela Kwefilimu Encane

Ukucatshangelwa kwedizayini yezinzwa zengcindezi emincane yefilimu kuhloswe ukuqinisekisa ukusebenza kwazo, ukwethembeka, nokuzinza ezinhlelweni ezihlukene.

Idizayini Yesakhiwo

Idizayini yesakhiwo sezinzwa zengcindezi emincane yefilimu kumele iqinisekise ukuzinza nokuqina kwemishini ngenkathi igcina ukuzwela nokunemba. Lokhu kudinga ukuthi abaklami bangacabangi nje kuphela izici ezibonakalayo zefilimu elincanyana kodwa futhi nomthwalo wemishini kanye nengcindezi yemvelo ezinhlelweni zokusebenza zangempela. Idizayini yesakhiwo senzwa kufanele imelane nezingcindezi zemishini ezihlukahlukene kanye nezinguquko zemvelo kuyilapho igcina isignali ephumayo ezinzile.

Ukuzwela

Ukuzwela kuyisici esibalulekile ekwakhiweni kwezinzwa zengcindezi, okuthonywa ukukhethwa kwezinto ezibonakalayo, ukujiya kwefilimu emincane, kanye nobuchwepheshe bokukhiqiza. Izinzwa ezizwela kakhulu zingathola izinguquko zengcindezi emincane, okubalulekile ekukaleni ngokunemba nokulawula izinhlelo zokusebenza. Ukukhetha impahla kuthinta ngokuqondile ukuzwela kwezinzwa; izinto ezihlukene zinezakhiwo ezihlukene zemishini nezikagesi, ezifanele izidingo zohlelo lokusebenza ezahlukene. Ukujiya kwefilimu encane nakho kuyisici esibalulekile; uma ifilimu iba mncane, iba nomuzwa ophakeme, kodwa lokhu kungase kunciphise amandla okusebenza, kudinge ukulingana phakathi kokuzwela namandla.

Ukunemba Nokunemba

Ukuzuza ukunemba okuphezulu nokunemba kuzinzwa zokucindezela kwefilimu emincane kudinga ukuklama ngokucophelela nezinqubo zokukhiqiza ukuze kuqinisekiswe ukwethembeka kokulinganisa nokuphindaphinda. Lokhu kufaka phakathi ukulawula ngokunembile ukujiya nokufana kwefilimu elincanyana, ukukhetha ama-substrates afanelekile, nokuthuthukisa izinqubo zokukhiqiza. Noma yikuphi ukuchezuka okuncane enqubweni yokukhiqiza kungathinta ukusebenza kwenzwa, kwenze ukulawulwa kwekhwalithi okuqinile nokuhlolwa kudingeke.

Izimpawu Zokusebenza Isikhathi sokuphendula

Izinzwa zengcindezi yefilimu ezacile ngokuvamile zinesikhathi sokuphendula esisheshayo, esibalulekile ezinhlelweni eziguqukayo ezidinga ukugadwa kwengcindezi yesikhathi sangempela. Isikhathi sokuphendula esisheshayo siqinisekisa ukuthi inzwa ingathwebula ngokushesha izinguquko zengcindezi, inikeze usekelo lwedatha yesikhathi sangempela kuzinhlelo zokusebenza emikhakheni efana ne-industrial automation, izinsiza zezokwelapha, kanye ne-aerospace.

Ukuqina

Ukukhetha izinto ezifanele kanye nokwamukela amasu okukhiqiza athembekile kuthuthukisa ukuqina kwezinzwa zokucindezela kwefilimu emincane, okuqinisekisa ukwethembeka kwesikhathi eside. Ukuqina kubalulekile ekusebenzeni okuzinzile kwesikhathi eside kwezinzwa, ikakhulukazi lezo ezisebenza ngaphansi kwezimo zemvelo ezinzima, njengamazinga okushisa aphezulu, umswakama ophezulu, noma izindawo ezibolayo.

Ukuzinza Kwemvelo

Izinzwa zokucindezela kwefilimu ezacile kufanele zigcine ukusebenza okungaguquki ngaphansi kwezimo ezihlukahlukene zemvelo, okuhlanganisa ukushintshashintsha kwezinga lokushisa, umswakama, nokucindezeleka komshini. Lokhu kudinga izinzwa ukuthi zibe nokuzinza okuhle kwemvelo, zikwazi ukusebenza ngaphakathi kwebanga lokushisa elibanzi, futhi zingazweli izinguquko zomswakama kanye nokucindezeleka komshini. Ukukhethwa kwezinto kanye nomklamo wokupakisha kudlala indima ebalulekile ekuqinisekiseni ukuzinza kwemvelo kwezinzwa.

Ukusetshenziswa kwezinzwa ze-Thin-Film Pressure

Embonini yezimoto, izinzwa zengcindezi encane yefilimu zisetshenziswa ezinhlelweni zokuqapha ingcindezi yamathayi (TPMS) ukuze zinikeze idatha yesikhathi sangempela yengcindezi yesondo, kuthuthukiswe ukuphepha nokusebenza. Kumasistimu okuphatha injini, lezi zinzwa ziqapha uphethiloli nomoya, ziqinisekisa ukusebenza kahle kwenjini nokusebenza kahle. Ukwengeza, amasistimu okuphepha ezimotweni njengama-airbag namasistimu okubhuleka ancike kuzinzwa zengcindezi yefilimu emincane ukuze kukale ingcindezi eqondile kanye nokwenza kusebenze ngesikhathi.

Emkhakheni wezokwelapha, izinzwa zokucindezela kwefilimu emincane zisetshenziswa eziqapheni zomfutho wegazi, zinikeza izilinganiso ezinembile nezingahlaseli ezibalulekile ekunakekelweni kwesiguli nokuxilongwa. Zibuye zisetshenziswe ezinzwa ezifakelwayo zokuqapha okuqhubekayo komzimba, ukuthuthukisa imiphumela yokwelashwa kwesiguli. Imishini yezokwelapha egqokekayo, njengezilandeleli zokufaneleka neziqaphi zezempilo, zisebenzisa lezi zinzwa ukulandelela izimpawu ezibalulekile nemisebenzi yomzimba.

Emkhakheni we-aerospace, izinzwa zokucindezela kwefilimu emincane zisetshenziselwa ukuqapha ingcindezi yekhabhinethi, ukuqinisekisa ukucindezela kwekhabethe elilungile lokunethezeka nokuphepha kwabagibeli. Zibuye zisetshenziselwe ukuqapha impilo yesakhiwo, ekwazi ukubona izinkinga ezingaba khona ngaphambi kokuba zibe zimbi kakhulu. Ngaphezu kwalokho, lezi zinzwa zibalulekile ezinhlelweni zokulawula imvelo yemikhumbi-mkhathi, ziqinisekisa izimo ezinzile zabasebenzi nemishini.

Kuzicelo zezimboni, izinzwa zokucindezela kwefilimu emincane zisetshenziselwa ukulawula inqubo enembile, ukuqinisekisa ukusebenza kahle nokusebenza kahle. Amasistimu wamarobhothi athembele kulezi zinzwa ukuze uthole impendulo ethintekayo nokuzwa ingcindezi, athuthukise ukusebenza kwawo namandla. Amasistimu okuphepha ezimbonini aphinde asebenzise izinzwa zengcindezi yamafilimu amancane ukuze abone futhi aphendule izinguquko zengcindezi, avimbele izingozi futhi aqinisekise ukuphepha kwezisebenzi.

imibuzo ejwayelekile ukubuzwa

Yiziphi izinzuzo eziyinhloko zezinzwa zokucindezela kwefilimu encane?

Izinzwa ze-Thin-film pressure zinikeza ukuzwela okuphezulu, i-miniaturization, nokuthembeka okuthuthukisiwe, okuzenza zilungele izinhlelo zokusebenza ezihlukahlukene. Ukuzwela kwabo okuphezulu kuzivumela ukuthi zithole izinguquko zengcindezi emincane, idizayini encane izenza zifanelekele izinhlelo zokusebenza ezinesikhala, futhi ukwethembeka okuthuthukisiwe kuqinisekisa ukusebenza okuzinzile kwesikhathi eside ezindaweni ezinokhahlo.

Ingabe izinzwa zokucindezela kwefilimu emincane zihluke kanjani kuzinzwa zendabuko?

Izinzwa zengcindezi yefilimu izacile zinembe kakhudlwana, zihlangene, futhi ngokuvamile zihlala isikhathi eside kunezinzwa zenqwaba evamile. Zinikeza ukusebenza okungcono ezinhlelweni ezifunayo, ziyakwazi ukusebenza ngaphakathi kwebanga elibanzi lokushisa nezingcindezi, futhi zinokuzwela okuphezulu nesivinini sokuphendula. Lezi zici zenza izinzwa zefilimu emincane ziphumelele ezinhlelweni eziningi ezidingeka kakhulu.

Yiziphi izinto ezisetshenziswa kakhulu ezinzwa zokucindezela kwefilimu encane?

Izinto ezijwayelekile zifaka izinsimbi ezifana negolide neplatinamu, ama-semiconductors afana ne-silicon, nezinto ezithuthukisiwe njenge-graphene. Igolide neplatinamu zisetshenziswa kabanzi ekwenzeni kwazo okuhle kakhulu kanye nokumelana nokugqwala kuma-electrode enzwa. I-silicon ivame ukusetshenziswa kumafilimu amancanyana e-semiconductor ngenxa yezakhiwo zayo ezinhle nezici ze-elekthronikhi, kuyilapho i-graphene ibhekwa njengenketho efanelekile yezinto ezinzwa zesikhathi esizayo ngenxa yezakhiwo zayo zikagesi ezivelele namandla emishini.

Yiziphi izimboni ezizuza kakhulu kuzinzwa zokucindezela kwefilimu emincane?

Izimboni zezimoto, ezokwelashwa, i-aerospace, umthengi kagesi, nezimboni ezishintshayo zizuza kakhulu kuzinzwa zengcindezi yefilimu emincane. Embonini yezimoto, lezi zinzwa zisetshenziselwa ukuqapha umfutho wesondo kanye nokuphathwa kwenjini; emkhakheni wezokwelapha, zisetshenziselwa ukuqapha umfutho wegazi kanye nezinzwa ezifakelwayo; emkhakheni we-aerospace, asetshenziselwa ukuqapha ingcindezi ye-cabin kanye nokuqapha impilo yesakhiwo; kuma-electronics abathengi, bathuthukisa ulwazi lwabasebenzisi bemishini ehlakaniphile; nakuma-automation ezimbonini, asetshenziselwa ukulawula inqubo kanye namarobhothi.

Yiziphi izindlela zokukhiqiza ezisetshenziselwa izinzwa zokucindezela kwefilimu emincane?

Amasu ajwayelekile ahlanganisa ukuphalaza, i-chemical vapor deposition (CVD), i-physical vapor deposition (PVD), kanye ne-atomic layer deposition (ALD). Lawa masu angakwazi ukulawula ngokunembile ukujiya, ukufana, nokwakheka kwefilimu elincanyana, aqinisekise ukusebenza kwezinzwa nokwethembeka. I-Sputtering iyindlela esetshenziswa kabanzi yokubeka umhwamuko wokukhiqiza amafilimu amancane ensimbi; Amasu e-CVD kanye ne-PVD avame ukusetshenziselwa ukufaka ama-semiconductors nezinto zokuvikela; I-ALD ingakwazi ukulawula ubukhulu bamafilimu amancane ezingeni le-athomu, afanele ukulungiselela amafilimu amancane kakhulu.

Izithenjwa:

1.U-Ohring, M. (2001). "Isayensi Yezinto Zamafilimu Amancane." I-Academic Press.

Isikhathi sokuthumela: Jun-28-2024