1. Isingeniso

Amasistimu we-hydraulicziwubuchwepheshe obuyisisekelo embonini yesimanje, ebalulekile ekudluliseni nasekulawuleni amandla emishini, ekukhiqizeni, nasezinhlelweni zamandla ukuze kuqinisekiswe ukusebenza kahle kwemishini. Ngaphakathi kwalezi zinhlelo, izinzwa zengcindezi ephezulu zidlala indima ebalulekile, njengoba kufanele zinikeze ukuqapha kwengcindezi okunembile nokuzinzile ezindaweni ezicindezelayo neziyinkimbinkimbi. Njengoba izimfuno zezimboni ziqhubeka nokukhula, ubuchwepheshe bezinzwa buye bavela, ngezinto zokwakha ze-ceramic nezengilazi ezivela njengezinto ezimbili ezibalulekile zenzwa.

Izinto ze-Ceramic zidume ngamandla azo aphezulu, ukumelana nokushisa, nokumelana nokugqwala, zigcina ukusebenza okuhle kakhulu ngaphansi kwezimo ezimbi kakhulu. Zisetshenziswa kabanzi ekufuneni izicelo zezimboni. Ngakolunye uhlangothi, ubuchwepheshe bengilazi obufakwe ingilazi busebenzisa impushana yengilazi enezinga eliphezulu lokushisa ukuze kwakhiwe izakhiwo ezingenamthungo, ezingena-O-ring-free, ezivalwe kakhulu, okwenza ifaneleke ngokukhethekile ukuvimbela ukuvuza kwamafutha ezinhlelweni zamanzi. Lesi sihloko sizoqhathanisa ukusebenza kwalezi zinto ezimbili ekusetshenzisweni kukawoyela we-hydraulic, sihlole izinzuzo nezinkinga zazo ngokulandelana kwazo ukuze sisize abafundi benze ukukhetha okungcono kakhulu kwezimo ezihlukene zohlelo lokusebenza.

2. Izidingo Eziyisisekelo Zezinzwa ku-Hydraulic Systems

Izinzwa zokucindezela ezinhlelweni zamanzi kufanele zihlangabezane nezidingo ezibalulekile ezimbalwa zokuqinisekisa ukuphepha nokusebenza kahle kwesistimu. Okokuqala,ukumelana nokucindezelakubalulekile ngoba amasistimu asebenza ngogesi ngokuvamile asebenza ngaphansi kwengcindezi ephezulu kakhulu. Izinzwa zidinga ukusebenza ngokwethembeka ngaphansi kwalezi zimo zokucindezela okukhulu, ukuvimbela ukwehla kokusebenza noma ukwehluleka ngenxa yokuguquguquka kwengcindezi.

Okwesibili,ukufaka uphawu nokuvimbela ukuvuza kwamafuthazibaluleke kakhulu ekufakweni kukawoyela we-hydraulic. Ukuvuza kukawoyela akunciphisi ukusebenza kahle kwesistimu kuphela kodwa futhi kungabangela ukulimala kwemishini noma izingozi zokuphepha. Ngakho-ke, izinzwa kufanele zibe nekhono elihle lokuvala ukuze kuvinjwe ngempumelelo ukuvuza kukawoyela we-hydraulic, kuqinisekiswe ukusebenza okuzinzile kwesistimu isikhathi eside.

Ekugcineni,ukuzinza nokuqina kwesikhathi esidenazo ziyizidingo ezibalulekile zezinzwa ezinhlelweni zamanzi. Izinzwa kufanele zikwazi ukusebenza ngokwethembeka isikhathi eside endaweni enengcindezi ephezulu, izinga lokushisa eliphezulu ngaphandle kokulahlekelwa ukunemba kokulinganisa noma ukwehluleka ngenxa yezimo ezinzima. Lezi zidingo eziyisisekelo zinquma ukusebenza kwezinzwa ezihlukene ezinhlelweni ze-hydraulic futhi zinikeze isisekelo sokukhethwa kwezinto ezilandelayo.

3. I-Ceramic Materials ku-Hydraulic Oil Applications

Izimpawu Zempahla: I-Ceramic iwukuqina okuphezulu, imelana nokushisa, futhi imelana nokugqwala egcina ukusebenza okuzinzile ngaphansi kwezimo ezimbi kakhulu. Lezi zici zenza ama-ceramic cores afaneleke ikakhulukazi ukusetshenziswa ku-hydraulic oil media, lapho kudingeka khona ukusebenza okuzinzile kwesikhathi eside.

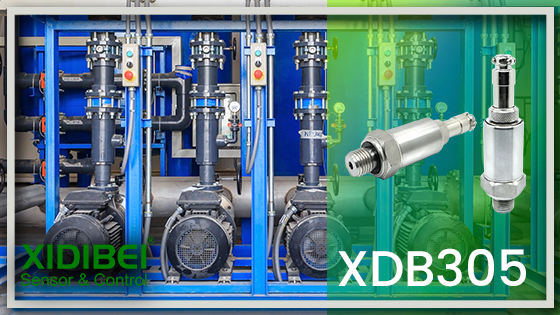

Izinzuzo: Ama-Ceramic cores asebenza kahle kakhulu ngaphansi kwezimo ze-vacuum ephezulu, ikakhulukazi mayelana nokuzinza kwesikhathi eside ezindaweni ezimbi kakhulu. Ngenxa yokuqina nokuqina kwezinto zobumba, ama-ceramic cores angakwazi ukumelana nokuguquguquka okukhulu kwengcindezi ngaphandle kokuguqulwa noma ukwehluleka. Ukwengeza, ama-ceramic cores ahlinzeka ngezilinganiso ezinembile nezizinzile ngisho nasezimeni ze-vacuum, ezinikeza umkhawulo ngaphezu kwezinye izinto ezinhlelweni ezithile ezikhethekile ze-hydraulic. I-XIDIBEIXDB305 uchungechungeisebenzisa lezi zici zezinto ze-ceramic, iyenze isebenze kabanzi ezindaweni eziyinkimbinkimbi zezimboni.

Ukubi: Naphezu kokusebenza kwawo okuhle kakhulu ezindaweni ezishisa kakhulu nezinomfutho ophezulu, ama-ceramic cores angase angavali kahle kuma-hydraulic oil media njengama-glass microfused cores. Ngokuyinhloko lokhu kungenxa yokuthi izinto zobumba ziqinile, okwenza kube nzima ukufeza izimpawu eziqinile ezinganikezwa ubuchwepheshe bengilazi be-microfused. Lokhu kusho ukuthi kwezinye izimo, ama-ceramic cores angase abeke engcupheni yokuvuza kukawoyela we-hydraulic, ikakhulukazi ngemva kokusetshenziswa isikhathi eside lapho ukuvala ukusebenza kungase kwehle. Lokhu kushiyeka kwenza ama-ceramic cores angakwazi ukulungela izinhlelo zokusebenza ezinezidingo zokuvala eziphakeme kakhulu uma kuqhathaniswa nama-cores afakwe ingilazi amancane. Ukwengeza, ama-ceramic cores afaneleka kakhulu ezindaweni ezinengcindezi ephansi(≤600 ibha)futhi azifaneleki izimo zokucindezela okukhulu.

4. I-Glass Microfused Materials ku-Hydraulic Oil Applications

Izimpawu Zempahla: Ubuchwepheshe be-Glass microfused inqubo esebenzisa impushana yengilazi enezinga eliphezulu lokushisa ukuze yakhe isakhiwo esingenamthungo nesivalwe kakhulu. Lobu buchwepheshe bufaneleka kakhulu imidiya kawoyela we-hydraulic ngoba ivimbela ngempumelelo ukuvuza koketshezi. Lesi sici se-glass microfused cores sibenza baphumelele kakhulu ezinhlelweni ezidinga izinga eliphezulu lokuvala, ikakhulukazi ezinhlelweni ezicindezela kakhulu amanzi.

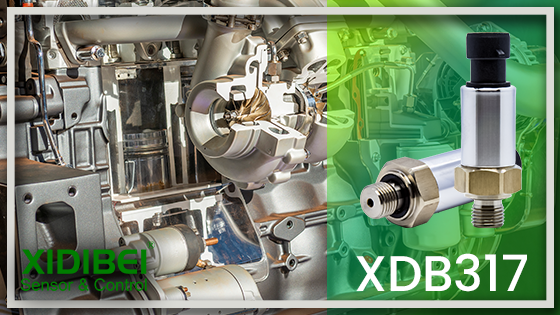

Izinzuzo: Inzuzo enkulu yengilazi yama-microfused cores ku-hydraulic oil media yikhono labo elihle lokuvala uphawu. Ukungabikho kwama-O-rings kususa izingozi zokuvuza ezingase zibe khona ezihlobene nezindlela zokuvala zendabuko, okwenza ama-cores afakwe ingilazi aphumelele ikakhulukazi ekuvimbeleni ukuvuza kukawoyela. I-XIDIBEIXDB317 uchungechunge, ngokusekelwe kulobu buchwepheshe, ingagcina ubuqotho bokuvalwa kwesikhathi eside ezinhlelweni zikawoyela we-hydraulic, inciphise ukwehluleka kwesistimu ngenxa yokuvuza. Lesi sici sibenza babe yinketho efanelekile yokuvimbela ukuvuza kukawoyela ezinhlelweni ezisebenza nge-hydraulic.

Ukubi: Kodwa-ke, ama-cores ama-microfused engilazi anemikhawulo ethile lapho esebenzelana nezindawo ze-vacuum. Ngenxa yokuklama kanye nezici ezibonakalayo, ama-cores microfused engilazi awakwazi ukunikeza izinga elifanayo lokuzinza nokunemba ezimeni ze-vacuum njengama-ceramic cores. Lokhu kunciphisa ukusebenza kwazo kwezinye izinhlelo zokusebenza ezikhethekile, njengezinhlelo eziyinkimbinkimbi zama-hydraulic ezidinga ukuphatha kokubili ukucindezela okuhle nokubi. Kulezi zimo, ama-cores microfused glass angase angahlangabezani nazo zonke izidingo zokulinganisa.

Ngokwenza ukuhlaziya okuningiliziwe kwalezi zinto ezimbili ezisetshenziswa kuwoyela we-hydraulic, abafundi bangaqonda kangcono izimo zabo zokusebenza nezici zokusebenza, banikeze ukwesekwa okuqinile kokukhetha ubuchwepheshe benzwa obufanele.

5. Ukuhlaziya Ngokuqhathanisa Nezimo Zokusebenza

Ukuhlaziya Ngokuqhathanisa: Kwimidiya kawoyela we-hydraulic, ama-ceramic kanye nengilazi ama-microfused cores ngayinye inamandla nobuthakathaka obuhlukile. Ama-Ceramic cores ahamba phambili ekuphikisweni kwengcindezi kanye nokuzinza kwesikhathi eside ezindaweni ezimbi kakhulu. Zisebenza kahle kakhulu ngaphansi kwezimo ze-vacuum kanye nezinga eliphezulu lokushisa, zigcina ukunemba kwesilinganiso esiphezulu futhi zimelana nokuphazanyiswa kwemvelo kwangaphandle. Kodwa-ke, ngenxa yezici zezinto ezibonakalayo, ama-ceramic cores angase angavali kahle njengama-microfused cores engilazi, okungase kuholele ezinkingeni zokuvuza ekusetshenzisweni kukawoyela we-hydraulic. Ngakho-ke, ngokufingqiwe, ama-ceramic cores afanele izicelo zokucindezela okuphansi(≤600 ibha), kuyilapho kungokwezimo zokucindezela okukhulu(kufika ku-3500 bar), izinzwa zengilazi ezinama-microfused ziyanconywa.

Ngokuphambene, amandla engilazi ama-microfused cores asekhonweni lawo lokuvala eliphezulu, okuwenza asebenze kahle kakhulu ekuvimbeleni ukuvuza kukawoyela we-hydraulic. Idizayini ye-O-ring-free ayigcini nje ngokuthuthukisa ukwethembeka okuphelele kwenzwa kodwa futhi inciphisa ukwehluleka okungenzeka ngenxa yokuwohloka kwezimpawu. Kodwa-ke, ama-cores ama-microfused engilazi abuthakathaka kakhulu endaweni ye-vacuum futhi awakwazi ukunikeza ukuzinza okufanayo ezilinganisweni njengama-ceramic cores.

Izincomo zesimo sohlelo lokusebenza: Lapho ukhetha inzwa efanele, kubalulekile ukulinganisela izidingo zohlelo lokusebenza. Uma isistimu ye-hydraulic idinga ukuvalwa okuphezulu nokuvimbela ukuvuza kukawoyela, ama-glass microfused cores ayisinqumo esihle, ikakhulukazi ezindaweni ezicindezelayo ezinhle kanye nezinhlelo ezidinga ukuvala uphawu okuzinzile isikhathi eside, njengeziteshi zokumpompa kanye nezinhlelo zokuhlanza amanzi. Ngakolunye uhlangothi, kumasistimu adinga ukusingatha kokubili ukucindezela okuhle nokubi noma ukusebenza ngaphansi kwezimo zokushisa nezingcindezi ezidlulele, ama-ceramic cores angase afaneleke kakhulu, anikeze ukunemba okuphezulu kokulinganisa nokuzinza ngaphansi kwalezi zimo ezinzima.

6. Isiphetho

Sengiphetha, ama-ceramic kanye nengilazi ama-microfused cores ngayinye inezinzuzo zayo ezihlukile kanye nezicelo ezifanele. Ama-Ceramic cores, anokumelana nokucindezela kwawo okuhle kakhulu nokuzinza ezindaweni ezidlulele, enza kahle kakhulu ezinhlelweni ezidinga ukuphathwa kwengcindezi eyinkimbinkimbi. Ngokuphambene, ama-cores afakwe ingilazi amancane, ngokuvaleka kwawo okuphakeme nokuvimbela ukuvuza kukawoyela, abusa ezinhlelweni zamanzi adinga ubuqotho bokuvalwa okuphezulu.

Ukukhetha i-sensor efanelekile kubalulekile ekuqinisekiseni impilo ende kanye nokuthembeka okuphezulu kwamasistimu asebenza ngamanzi. Ngokukhetha ubuchwepheshe benzwa obufaneleka kakhulu obusekelwe ezidingweni ezithile zesistimu, kungenzeka ukuthuthukisa ukusebenza kahle kwesistimu, ukunciphisa ingozi yokwehluleka, nokuqinisekisa ukusebenza okuphephile nokuzinzile ngaphansi kwezimo ezihlukahlukene. Le ndlela yokukhiqiza ayigcini nje ngokuthuthukisa ukusebenza kahle kokukhiqiza kodwa futhi yehlisa izindleko zokuyilungisa futhi inwebe neminyaka yokuphila kwemishini.

Isikhathi sokuthumela: Aug-28-2024