Esilinganisweni sokucindezela, ungase uqaphele ukuthi imiphumela yokulinganisa ayibonisi ngokushesha izinguquko kungcindezi yokufaka noma ihambisane ngokugcwele lapho ingcindezi ibuyela esimweni sayo sokuqala. Isibonelo, uma usebenzisa isikali sokugezela ukukala isisindo, inzwa yesikali idinga isikhathi ukuze izwe kahle futhi izinze ukufundwa kwesisindo sakho. Iisikhathi sokuphendulakwenzwa kuholela ekushintshashintsheni kwedatha kokuqala. Uma inzwa isilungisa umthwalo futhi iqeda ukucutshungulwa kwedatha, ukufundwa kuzobonisa imiphumela ezinzile.Lokhu akukona ukonakala kwenzwa kodwa isici esivamile samadivayisi amaningi wokulinganisa we-elekthronikhi, ikakhulukazi uma kuhlanganisa ukucutshungulwa kwedatha yesikhathi sangempela kanye nempumelelo yesimo esiqinile. Lesi simo singabizwa ngokuthi i-sensor hysteresis.

Iyini i-hysteresis ezinzwa zokucindezela?

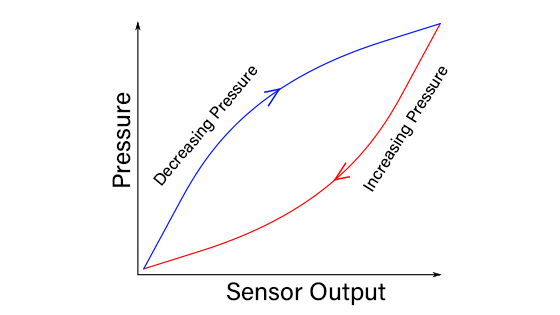

Inzwai-hysteresisngokuvamile kubonakala lapho kukhona ushintsho kokokufaka (okufana nezinga lokushisa noma ukucindezela), futhi isignali yokuphumayo ayilandeli ngokushesha ushintsho lokokufaka, noma lapho okokufaka kubuyela esimweni sayo sangempela, isignali yokuphumayo ayibuyeli ngokugcwele esimweni sayo sokuqala. . Lesi senzakalo singabonakala kwijika lesici senzwa, lapho kukhona ijika elimise okweluphu phakathi kokungenayo nokuphumayo, kunomugqa oqondile. Ngokuqondile, uma uqala ukukhulisa okokufaka kusuka enanini elithile, okukhiphayo kwenzwa nakho kuzokhuphuka ngokufanele. Nokho, lapho okokufaka kuqala ukwehla kubuyele endaweni yokuqala, uzothola ukuthi amanani okukhiphayo aphezulu kunamanani okukhiphayo asekuqaleni phakathi nenqubo yokunciphisa, akha iluphu nomai-hysteresis loop. Lokhu kubonisa ukuthi phakathi nenqubo ekhulayo nokunciphayo, inani lokufaka elifanayo lihambisana namanani amabili ahlukene okukhiphayo, okuwukuboniswa okunembile kwe-hysteresis.

Umdwebo ubonisa ubudlelwano phakathi kokuphumayo kanye nokucindezela okusetshenzisiwe kunzwa yokucindezela phakathi nenqubo yokufaka isicelo sokucindezela, emelelwe ngendlela yejika le-hysteresis. I-eksisi evundlile imele okukhiphayo kwenzwa, futhi i-eksisi eqondile imele ukucindezela okusetshenzisiwe. Ijika elibomvu limelela inqubo lapho okukhiphayo kwenzwa kukhuphuka ngokucindezela okwandayo kancane kancane, okubonisa indlela yokuphendula ukusuka kophansi kuya kophezulu. Ijika elihlaza okwesibhakabhaka libonisa ukuthi njengoba ingcindezi esetshenzisiwe iqala ukwehla, okukhiphayo kwenzwa nakho kuncipha, kusukela ekucindezelweni okuphezulu kuya phansi, okubonisa ukusabela kwenzwa ngesikhathi sokuthulula ingcindezi. Indawo ephakathi kwamajika amabili, i-hysteresis loop, ibonisa umehluko ekuphumeni kwenzwa ezingeni elifanayo lokucindezela ngesikhathi sokulayisha nokuthulula, ngokuvamile okubangelwa izakhiwo ezibonakalayo kanye nesakhiwo sangaphakathi senzwa yenzwa.

Izizathu ze-Pressure Hysteresis

I-hysteresis phenomenon inizinzwa zokucindezelaithonywa kakhulu izici ezimbili ezinkulu, ezisondelene kakhulu nezakhiwo zomzimba nendlela yokusebenza yenzwa:

- I-Material's elastic hysteresis Noma iyiphi into izoba sezingeni elithile lokuwohloka okunwebekayo lapho ingaphansi kwamandla angaphandle, ukusabela okuqondile kwento kumandla asetshenzisiwe. Lapho amandla angaphandle esuswa, impahla izama ukubuyela esimweni sayo sokuqala. Kodwa-ke, lokhu kuthola akuphelele ngenxa yokungafani phakathi kwesakhiwo sangaphakathi sempahla kanye nezinguquko ezincane ezingahlehliseki kusakhiwo esincane sangaphakathi phakathi nokulayisha nokulayishwa okuphindaphindiwe. Lokhu kuholela ekubambezelekeni kokukhishwayo kokuziphatha kokusebenza ngesikhathi sokulayisha okuqhubekayo nokukhipha izinqubo, ezaziwa ngokuthii-elastic hysteresis. Lesi simo sibonakala ikakhulukazi ekusetshenzisweni kweizinzwa zokucindezela, njengoba izinzwa ngokuvamile zidinga ukukala futhi ziphendule izinguquko zengcindezi ngokunembile.

- Ukungqubuzana Ezingxenyeni eziwumshini zenzwa yokucindezela, ikakhulukazi lezo ezihlanganisa izingxenye ezihambayo, ukungqubuzana akunakugwenywa. Lokhu kungqubuzana kungase kuvele koxhumana nabo abangaphakathi kwenzwa, njengendawo yokuxhumana eslayidayo, amabherengi, njll. Uma inzwa ithwala ingcindezi, lawa maphoyinti okungqubuzana angavimbela ukunyakaza okukhululekile kwezakhiwo zokukhanda zangaphakathi zenzwa, okubangele ukubambezeleka phakathi kokuphendula kwenzwa kanye ukucindezela kwangempela. Lapho ukucindezela kuthululwa, amandla afanayo okungqubuzana angase futhi avimbele izakhiwo zangaphakathi ukuthi ziyeke ngokushesha, ngaleyo ndlela futhi zibonise i-hysteresis phakathi nesigaba sokuthulula.

Lezi zici ezimbili zihlangene ziholela ku-hysteresis loop ebonwa kuzinzwa phakathi nokuhlolwa okuphindaphindiwe kokulayisha nokuthulula, isici esivame ukukhathaza kakhulu izinhlelo zokusebenza lapho ukunemba nokuphindaphinda kudingwa kakhulu. Ukuze kuncishiswe umthelela wale nto ye-hysteresis, ukuklama ngokucophelela nokukhetha okubalulekile kwenzwa kubalulekile, futhi ama-algorithms esofthiwe angase adingeke ukuze kunxeshezelwe le hysteresis ezinhlelweni zokusebenza.

I-hysteresis phenomenon inizinzwa zokucindezelakuthonywa yizici ezihlukahlukene ezihlobene ngokuqondile nezakhiwo zenzwa namakhemikhali kanye nendawo yokusebenza kwayo.

Yiziphi izici eziholela ku-hysteresis yezinzwa?

1. Izinto ezibonakalayo

- I-Elastic modulus: Imoduli enwebekayo yezinto inquma izinga lokuwohloka okunwebekayo lapho kuphoqelelwa. Izinto ezine-elastic modulus ephakeme zikhubaza kancane, futhi zazoi-elastic hysteresisingase ibe ngaphansi ngokuqhathaniswa.

- Isilinganiso se-Poisson: Isilinganiso sika-Poisson sichaza isilinganiso sokufinyezwa kwecala ukuya ekunwetshweni kwe-longitudinal kokokusebenza lapho kuphoqelelwe, okuphinde kuthinte ukuziphatha kokubalulekile phakathi nokulayisha nokuthulula.

- Isakhiwo sangaphakathi: I-microstructure yezinto ezibonakalayo, okuhlanganisa ukwakheka kwekristalu, amaphutha, nokuhlanganisa, kuthinta ukuziphatha kwayo komshini nezici ze-hysteresis.

2. Inqubo yokukhiqiza

- Ukunemba komshini: Ukunemba kwengxenye yenzwa kuthinta ngqo ukusebenza kwayo. Izingxenye ezinokunemba okuphezulu zilingana kangcono, zinciphisa ukungqubuzana okwengeziwe nokugxilisa ingqondo yengcindezi okubangelwa ukungalingani kahle.

- Ubulukhuni bobuso: Ikhwalithi yokwelashwa okungaphezulu, njengokugwedla kwendawo, ithinta ubukhulu bokungqubuzana, ngaleyo ndlela ibe nomthelela ekuphenduleni kwenzwa kanye ne-hysteresis.

- Ukushintsha kwezinga lokushisa kuthinta izici ezibonakalayo zezinto ezibonakalayo, njenge-elastic modulus kanye ne-friction coefficient. Amazinga okushisa aphezulu ngokuvamile enza izinto ezisetshenziswayo zithambe, zehlise i-elastic modulus futhi zikhule ukungqubuzana, ngaleyo ndlela andise i-hysteresis. Ngokuphambene, amazinga okushisa aphansi angenza izinto zibe nzima futhi zibe brittle, kuthinte i-hysteresis ngezindlela ezahlukene.

3. Izinga lokushisa

- Ukushintsha kwezinga lokushisa kuthinta izici ezibonakalayo zezinto ezibonakalayo, njenge-elastic modulus kanye ne-friction coefficient. Amazinga okushisa aphezulu ngokuvamile enza izinto ezisetshenziswayo zithambe, zehlise i-elastic modulus futhi zikhule ukungqubuzana, ngaleyo ndlela andise i-hysteresis. Ngokuphambene, amazinga okushisa aphansi angenza izinto zibe nzima futhi zibe brittle, kuthinte i-hysteresis ngezindlela ezahlukene.

Izingozi

Ukuba khona kwe-hysteresisizinzwa zokucindezelakungabangela amaphutha okulinganisa, kuthinte ukunemba nokuthembeka kwenzwa. Kuzinhlelo zokusebenza ezidinga izilinganiso zokunemba okuphezulu, njengokulawula inqubo yemboni enembayo kanye nokuqapha okubalulekile kwemishini yezokwelapha, i-hysteresis ingaholela emaphutheni abalulekile okulinganisa futhi ibangele nokuba lonke uhlelo lokulinganisa lwehluleke. Ngakho-ke, ukuqonda nokunciphisa umthelela we-hysteresis kuyingxenye ebalulekile yokuqinisekisa ukusebenza kahle nokunembile kwe-hysteresis.izinzwa zokucindezela.

Izixazululo ze-Hysteresis ku-Pressure Sensors:

Ukuqinisekisa imiphumela ephansi kakhulu ye-hysteresis kuizinzwa zokucindezela, abakhiqizi bathathe izinyathelo ezibalulekile ezimbalwa zokuthuthukisa ukusebenza kwezinzwa:

- Ukukhetha izinto ezibonakalayo: Ukukhethwa kwezinto kudlala indima ebalulekile ku-hysteresis. Ngakho-ke, abakhiqizi bakhetha ngokucophelela izinto ezibalulekile ezisetshenziswa ekwakhiweni kwezinzwa, njengama-diaphragm, izimpawu, kanye noketshezi lokugcwalisa, ukuze baqinisekise ukuthi babonisa i-hysteresis encane ngaphansi kwezimo ezihlukene zokusebenza.

- Ukwenziwa ngcono kwedizayini: Ngokuthuthukisa ukwakheka kwesakhiwo sezinzwa, njengokuma, usayizi, nogqinsi lwama-diaphragm, kanye nezindlela zokuvala ngokugcwele, abakhiqizi banganciphisa ngempumelelo i-hysteresis ebangelwa ukungqubuzana, ukungqubuzana okuqinile, nokuguqulwa kwezinto.

- Ukwelashwa kokuguga: Izinzwa ezisanda kukhiqizwa zingabonisa i-hysteresis yokuqala ebalulekile. Ngokusebenzisaukwelashwa ukugugakanye nezinhlelo ezithile zokuhlola, izinto zokwakha zingasheshiswa ukuze zizinze futhi zivumelane nezimo, ngaleyo ndlela kuncishiswe le hysteresis yokuqala. Isithombe esingezansi sibonisa i-XDB305okwenzekayoukwelashwa ukuguga.

- Ukulawula ukukhiqiza okuqinile: Ngokulawula ngokuqinile ukubekezelelana nekhwalithi phakathi nenqubo yokukhiqiza, abakhiqizi baqinisekisa ukuvumelana kwenzwa ngayinye futhi banciphise umthelela wokuhluka kokukhiqiza ku-hysteresis.

- Ukulinganisa okuthuthukisiwe nesinxephezelo: Abanye abakhiqizi basebenzisa ubuchwepheshe bokunxeshezelwa kwedijithali obuthuthukisiwe nezindlela zokulinganisa amaphuzu amaningi ukuze benze imodeli enembile futhi balungise i-hysteresis ekuphumeni kwenzwa.

- Ukuhlolwa kokusebenza nokugreda: Zonke izinzwa zihlolwa ngemininingwane ukuze zihlole izici zazo ze-hysteresis. Ngokusekelwe emiphumeleni yokuhlolwa, izinzwa ziyahlelwa ukuze kuqinisekiswe ukuthi imikhiqizo kuphela ehlangabezana namazinga athile e-hysteresis ekhishelwa emakethe.

- Ukuhlola ukuphila okusheshisiwe: Ukuqinisekisa ukuqina kokusebenza kwezinzwa phakathi nesikhathi sazo sokuphila esilindelekile, abakhiqizi benza izivivinyo zokuguga ezisheshayo nokuphila kumasampula ukuze baqinisekise ukuthi i-hysteresis ihlala ingaphakathi kwemikhawulo eyamukelekayo.

Lezi zinyathelo ezibanzi zisiza abakhiqizi ukuthi balawule ngempumelelo futhi banciphise i-hysteresis phenomenon kuizinzwa zokucindezela, iqinisekisa ukuthi izinzwa zihlangabezana nezidingo zokunemba okuphezulu nokuthembeka ezinhlelweni zokusebenza zangempela.

Isikhathi sokuthumela: May-09-2024