imikhiqizo

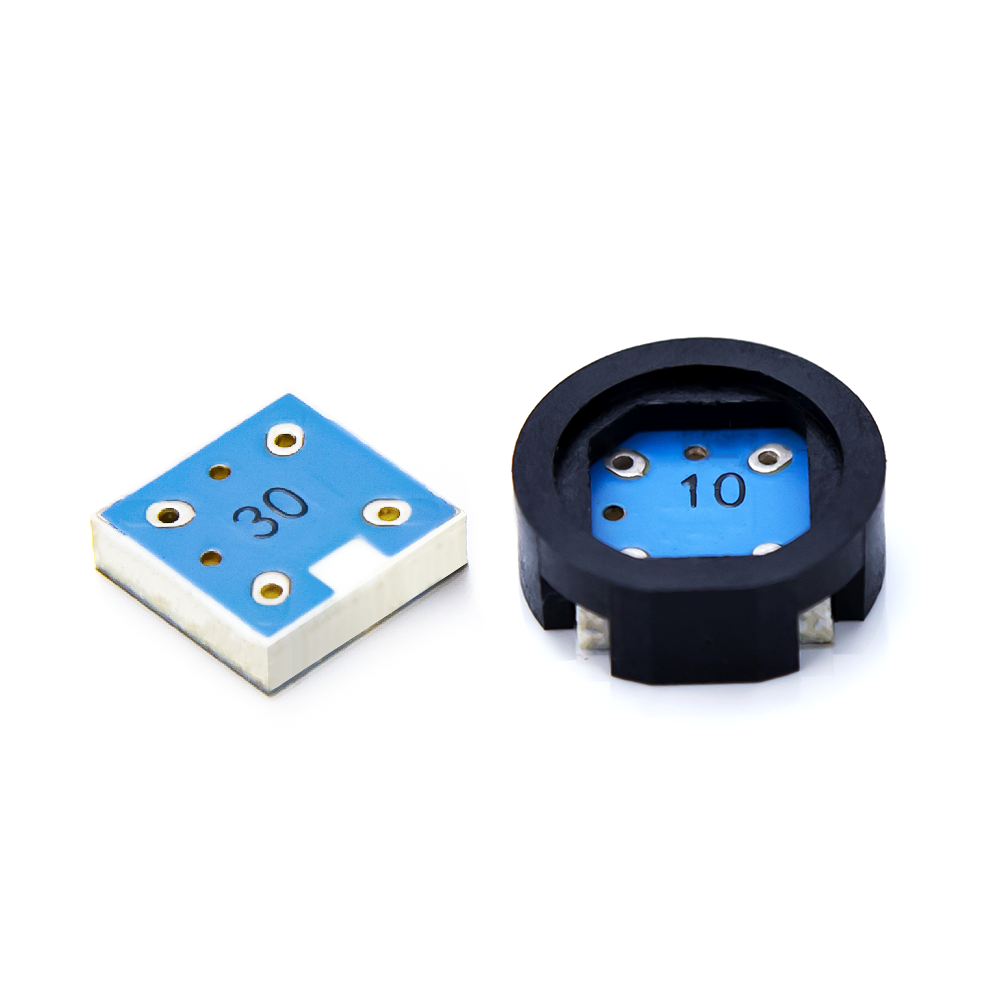

I-XDB100 Piezoresistive Monolithic Ceramic Pressure sensor

Izici

● Ukuzinza okuhle kakhulu kwesikhathi eside

● Isinxephezelo sezinga lokushisa esisebenzayo

Izicelo Ezijwayelekile

● Imboni

● Ivalvu, ukudlulisa, amakhemikhali, ubunjiniyela be-petrochemical, igeji yomtholampilo njll.

Imingcele Yezobuchwepheshe

| Ibanga lokucindezela | | Ubukhulu | φ(18/13.5)×(6.35/3.5) mm |

| Ingcindezi yokuqhuma | 1.15~3 izikhathi (ububanzi buyahluka) | I-voltage yokuhlinzeka | 0-30 VDC (ubukhulu) |

| I-impedance yomgwaqo webhuloho | | Okuphumayo kwebanga eligcwele | ≥2 mV/V |

| Izinga lokushisa lokusebenza | -40~+135℃ | Izinga lokushisa lesitoreji | -50~+150 ℃ |

| Ukunemba sekukonke (linear + hysteresis) | ≤±0.3% FS | Ukwehla kwezinga lokushisa (iziro nokuzwela) | ≤±0.03% FS/℃ |

| Ukuzinza kwesikhathi eside | ≤±0.2% FS/ngonyaka | Ukuphindaphinda | ≤±0.2% FS |

| I-Zero offset | ≤±0.2 mV/V | Ukumelana ne-insulation | ≥2 KV |

| Ukuzinza kwesikhathi eside kwephoyinti elinguziro @20°C | ±0.25% FS | Umswakama ohlobene | 0~99% |

| Ukuthintana okuqondile nezinto eziwuketshezi | 96% Al2O3 | Isisindo sengqikithi | ≤7g(okujwayelekile) |

Amanothi

1. Uma ufaka i-ceramic sensor core, kubalulekile ukugxila ekufakweni kokumiswa. Isakhiwo kufanele sifake indandatho yengcindezi engaguquki ukuze kukhawulwe indawo ye-sensor core futhi kuqinisekiswe ngisho nokusatshalaliswa kokucindezeleka. Lokhu kusiza ukugwema ukwehluka ekukhuleni kwengcindezi okungavela kubasebenzi abahlukene.

2. Ngaphambi kwe-welding, yenza ukuhlolwa okubonakalayo kwe-sensor pad. Uma i-oxidation ikhona endaweni yephedi (iyenze ibe mnyama), hlanza iphedi ngerabha ngaphambi kokulishisela. Ukwehluleka ukwenza kanjalo kungase kubangele ukuphuma kwesignali okungekuhle.

3. Uma ushisela izintambo zokuhola, sebenzisa itafula lokushisa elinokulawula ukushisa okubekwe ku-140-150 degrees. I-soldering iron kufanele ilawulwe cishe ngama-degree angama-400. I-flux esekelwe emanzini, engahlanjululwanga ingasetshenziselwa inaliti yokushisela, kuyilapho ukunamathisela okuhlanzekile kwe-flux kunconywa ngocingo lokushisela. Amalunga e-solder kufanele abe bushelelezi futhi angabi nama-burrs. Nciphisa isikhathi sokuthintana phakathi kwe-ayina e-soldering kanye nephedi, futhi ugweme ukushiya i-ayina e-soldering kuphedi yenzwa ngaphezu kwamasekhondi angu-30.

4. Ngemuva kokushisela, uma kunesidingo, hlanza i-flux esele phakathi kwamaphoyinti wokushisela usebenzisa ibhulashi elincane elinengxube yezingxenye ezingu-0.3 ze-ethanol ephelele kanye nezingxenye ezingu-0.7 zokuhlanza ibhodi lesifunda. Lesi sinyathelo sisiza ukuvimbela ukugeleza kwensalela ekukhiqizeni amandla e-parasitic ngenxa yomswakama, okungase kuthinte ukunemba kwesignali yokuphumayo.

5. Yenza ukutholwa kwesignali yokuphumayo kunzwa eshiselwe, uqinisekise isignali ephumayo ezinzile. Uma ukweqa idatha kwenzeka, inzwa kufanele ishiswe kabusha futhi ihlanganiswe kabusha ngemva kokudlulisa ukutholwa.

6. Ngaphambi kokulinganisa i-sensor post-assembly, kubalulekile ukubeka izingxenye ezihlanganisiwe ekucindezelekeni ukuze ulinganise ukucindezeleka komhlangano ngaphambi kokulinganisa isignali.

Ngokuvamile, ukugibela amabhayisikili okuphakeme nokuphansi kwezinga lokushisa kungasetshenziswa ukuze kusheshiswe ukulingana kwengcindezi yengxenye ngemva kwenqubo yokunwetshwa nokufinyezwa. Lokhu kungafezwa ngokubeka izingxenye ezingeni lokushisa -20℃ kuya ku-80-100℃ noma izinga lokushisa lekamelo libe ngu-80-100℃. Isikhathi sokufaka emazingeni okushisa aphezulu naphansi kufanele sibe okungenani amahora ama-4 ukuze kuqinisekiswe imiphumela emihle. Uma isikhathi sokufakelwa sisifushane kakhulu, ukusebenza kahle kwenqubo kuzoba sengozini. Izinga lokushisa lenqubo ethile kanye nesikhathi sokufakelwa kunganqunywa ngokuhlola.

7. Gwema ukunwaya i-diaphragm ukuze uvimbele ukulimala okungenzeka kumjikelezo wangaphakathi we-ceramic sensor core, okungase kuphumele ekusebenzeni okungazinzile.

8. Qaphela ngesikhathi sokukhweza ukuze uvimbele noma yimiphi imithelela engase ibangele ukungasebenzi kahle kwe-sensing core.

Sicela uqaphele ukuthi iziphakamiso ezingenhla zokuhlanganisa izinzwa ze-ceramic ziqondene ngqo nezinqubo zenkampani yethu futhi zingase zingasebenzeli njengamazinga ezinqubo zokukhiqiza amakhasimende.

Uku-oda Ulwazi