imikhiqizo

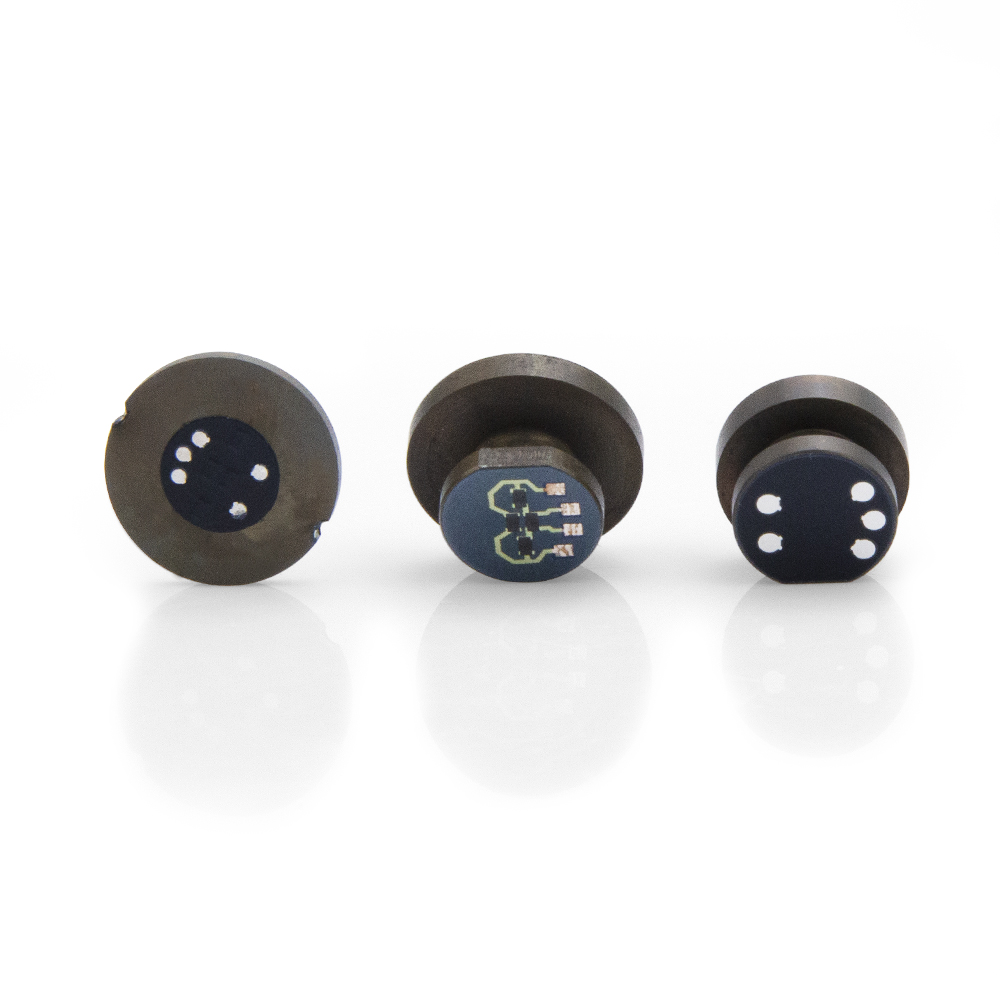

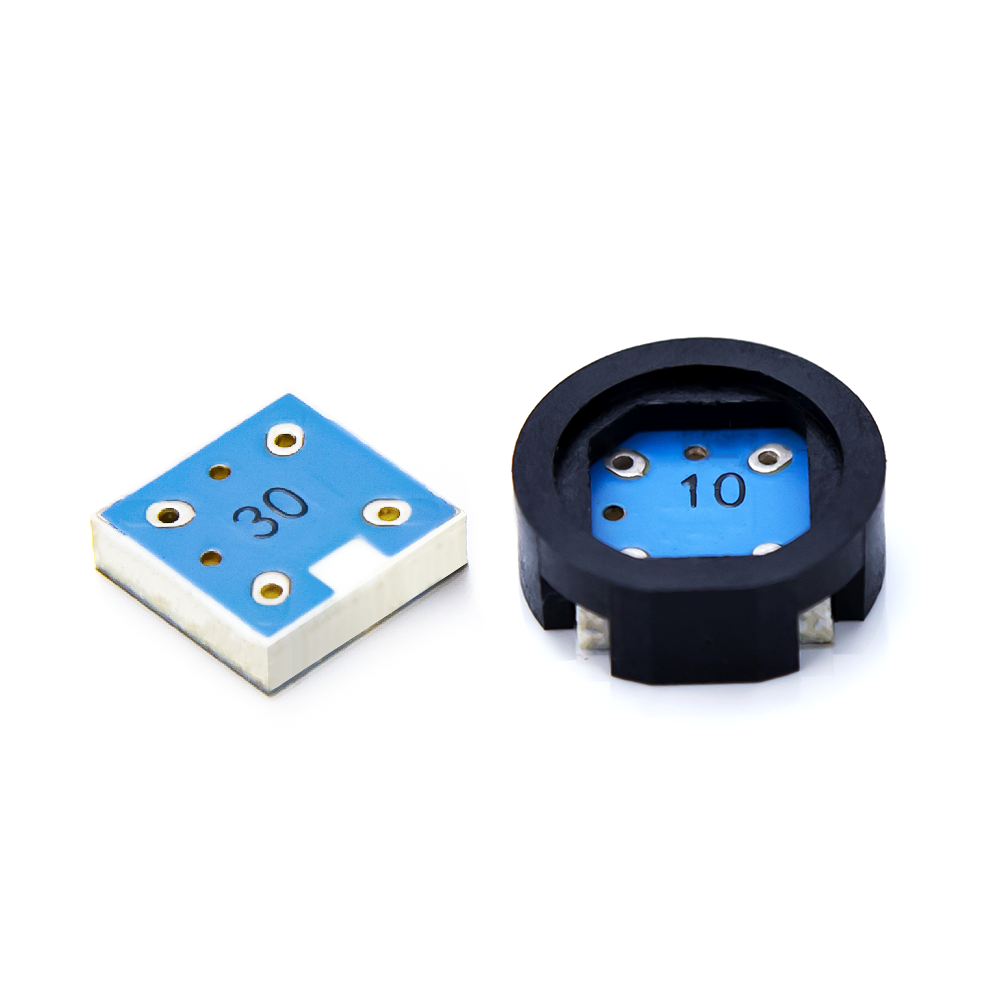

XDB103-9 Series Pressure Sensor Module

Izici

1. Iphutha: 1% ukusuka ku-0 ~ 8 5℃

2. Ibanga lokushisa eligcwele ( -40 ~ 125 ℃), iphutha: 2%

3. Ubukhulu buhambisana nezinzwa ze-ceramic piezoresistive

4. Ingcindezi yokulayisha ngokweqile: 200% FS, ingcindezi yokuqhuma: 300%FS

5. Imodi yokusebenza: I-gauge pressure

6. Imodi yokuphuma: ukuphuma kwe-voltage nokuphuma kwamanje

7. Ukwehla kwengcindezi yesikhathi eside: <0.5%

Izinhlelo zokusebenza ezijwayelekile

1. Inzwa yokucindezela komoya yemoto yezentengiselwano

2. Inzwa Yokucindezela Amafutha

3. Inzwa yokucindezela kwepompo yamanzi

4. Inzwa yokucindezela emoyeni ye-compressor

5. Inzwa yokucindezela kwe-air conditioning

6. Ezinye izinzwa zokucindezela ezindaweni zokulawula izimoto nezimboni

Izici zokusebenza

1. Ngaphakathi kwalolu bubanzi be-voltage yokusebenza, okukhiphayo kwemojula kugcina ubudlelwano obulinganayo kanye nomugqa.

2. I-Minimum Pressure Offset: Ibhekisela ku-voltage ephumayo yemojuli endaweni yokucindezela ephansi kakhulu phakathi kwebanga lokucindezela.

3. Okukhipha Isikali Esigcwele: Kubonisa amandla kagesi emojuli endaweni yokucindezela ephezulu phakathi kwebanga lokucindezela.

4. I-Span-Scale Egcwele: Ichazwa njengomehluko we-algebraic phakathi kwamanani okukhiphayo endaweni ephakeme kanye nencane yamaphoyinti okucindezela ngaphakathi kwebanga lokucindezela.

5. Ukunemba kuhlanganisa izici ezihlukahlukene, okuhlanganisa iphutha lomugqa, iphutha le-hysteresis lokushisa, iphutha le-pressure hysteresis, iphutha lezinga lokushisa eligcwele, iphutha lezinga lokushisa elinguziro, namanye amaphutha ahlobene.

6. Isikhathi Sokuphendula: Sibonisa isikhathi esisithathayo ukuze okokukhiphayo kuguquke ukusuka ku-10% ukuya ku-90% yenani lakho lethiyori.Ukuzinza kwe-Offset: Lokhu kumelela ukukhishwa kwemojuli ngemva kokubhekana namahora angu-1000 okucindezela kokushaya kanye nokuhamba ngebhayisikili.

Khawulela amapharamitha

1. Ukweqa izilinganiso eziphezulu ezishiwo kungaholela ekulimaleni kokusebenza noma ekulimaleni kwedivayisi.

2. Ama-currents amaningi okufakwayo nokuphumayo anqunywa ukuvinjelwa phakathi kokuphumayo kanye kokubili phansi kanye nokunikezwa kwamandla kumjikelezo wangempela.

Electromagnetic ukuhambisana EMC

Umkhiqizo uhambisana nalezi zindlela zokuhlola ze-EMC ezilandelayo:

1) Ukuphazamiseka kwe-pulse kwesikhashana emigqeni yamandla

Isisekelo esijwayelekile:I-ISO7637-2: “Ingxenye 2: Ukuqhutshwa kwesikhashana kukagesi emigqeni yokunikezela kuphela

| I-Puls No | Amandla kagesi | Ikilasi Lomsebenzi |

| 3a | -150V | A |

| 3b | +150V | A |

I-2) I-anti-interference yesikhashana yemigqa yesignali

Isisekelo esijwayelekile:I-ISO7637-3: “Ingxenye 3: Ukudluliswa kwesikhashana kukagesi nge-capacitive kanyeukuxhumanisa ngemigqa ngaphandle kwemigqa yokuhlinzeka

Izindlela zokuhlola: Imodi ye-CCC : a = -150V, b = +150V

Imodi ye-ICC:± 5V

Imodi ye-DCC:± 23V

Ikilasi Lomsebenzi: Ikilasi A

3) I-radiated immunity RF immunity-AL SE

Isisekelo esijwayelekile:I-TS ISO 11452-2 Izimoto zomgwaqo - Izindlela zokuhlola izingxenye zikagesi ukuphazamiseka okuvela ku-narrowband radiated electromagnetic energy - Ingxenye 2: Indawo ebiyelwe evikelekile ene-Absorber ”

Izindlela zokuhlola: I-Low-Frequency Horn Antenna: 400~1000MHz

I-antenna yenzuzo ephezulu: 1000 ~ 2000 MHz

Izinga lokuhlola: 100V/m

Ikilasi Lomsebenzi: Ikilasi A

4) Umjovo ophezulu wamanje we-RF immunity-BCI (CBCI)

Isisekelo esijwayelekile:I-TS ISO 11452-4 Izimoto zomgwaqo - Izindlela zokuhlola ingxenyekagesi ukuphazamiseka okuvela kumandla kazibuthe we-narrowband—Ingxenye 4:Umjovo wamanje oyinqwaba( BCI)

Ibanga lemvamisa: 1~400 MHz

Izikhundla zokuhlola umjovo: 150mm, 450mm, 750mm

Izinga lokuhlola: 100mA

Ikilasi Lomsebenzi: Ikilasi A

Dlulisa umsebenzi kanye nemidwebo yesici esiphumayo

1) Umsebenzi wokudlulisa

VPHUMA= Vs× ( 0.00066667 × PIN+0.1 ) ± (iphutha lokucindezela × isici sephutha lokushisa × 0.00066667 × Vs) lapho Vsinani le-voltage ye-module, iyunithi Volts.

I-PINinani lengcindezi yokungena, iyunithi i-KPa.

2) Umdwebo wezimpawu zokufaka nokuphumayo(VS=5 Vdc , T =0 kuya ku-85 ℃)

3 ) isici sephutha lokushisa

Qaphela: Isici sephutha lokushisa silayini phakathi -40~0 ℃ kanye no-85~125 ℃.

4) Umkhawulo wephutha lokucindezela

Ubukhulu bemojuli nezincazelo zephini

I-1) Indawo yenzwa yokucindezela

2) Izinyathelo Zokusebenzisa I-chip:

Ngenxa yenqubo yokukhiqiza ye-CMOS eyingqayizivele kanye nokupakishwa kwenzwa okusetshenziswa kumjikelezo we-conditioning we-chip, kubalulekile ukuvimbela umonakalo ongaba khona ovela kugesi omile ngesikhathi sokuhlanganiswa komkhiqizo wakho.Gcina lokhu okucatshangelwayo okulandelayo:

A) Misa indawo yokuphepha engaguquguquki, egcwele amabhentshi okusebenzela angaguquguquki, omaka betafula, omata baphansi, namabhande asehlakaleni omqhubi.

B) Ukuqinisekisa ukuthi amathuluzi nezinto zokusebenza ziphansi;cabanga ukusebenzisa i-anti-static soldering iron ukuze uhlanganise ngesandla.

C) Sebenzisa amabhokisi okudlulisa alwa nokungaguquguquki (qaphela ukuthi iziqukathi ezijwayelekile zepulasitiki nezensimbi azinazo izinto ezimelene ne-static).

D) Ngenxa yezici zokupakisha ze-sensor chip, gwema ukusebenzisa izinqubo zokushisela ze-ultrasonic ekukhiqizeni umkhiqizo wakho.

E) Qaphela ngesikhathi sokucubungula ukuze ugweme ukuvimbela ama-inlets omoya we-chip.